A high-tech minerals processing group increases capacity

LKAB is an international high-tech minerals group, specializing in the production of refined iron ore products for the steel industry, with sales primarily to European steel works. Other important markets are North Africa, the Middle East and Southeast Asia. The Swedish mineral company LKAB has a number of iron ore mines, refining plants and ore harbors in northern Sweden and Norway.

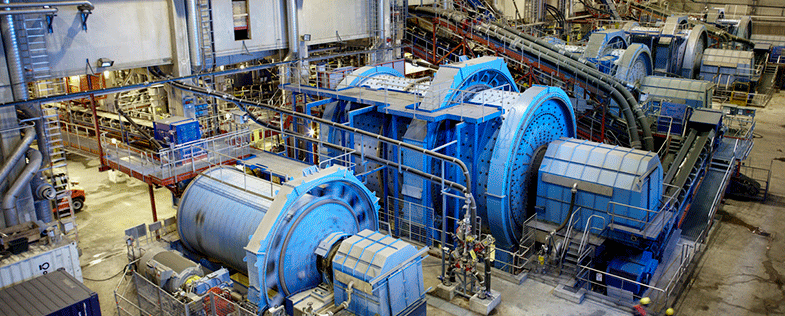

In 2008, LKAB commissioned a new processing and pelletizing plant in Kiruna, KA3/KK4, increasing its yearly overall production from 24 to 28 million tons of iron ore pellets. It is an enormous facility with the capacity to produce five million tons of pellets each year.

“Ball-shaped pellets are used in our customers’ blast furnaces and direct-reduction furnaces, and there are considerable quality requirements on the size of the balls, their roundness and quality,” says Mats Renfors, automation engineer at LKAB Kiruna. In the new plant, the iron ore is ground down to powder, cleaned of phosphorus in a flotation process, supplemented with a binding agent, drained and rolled into balls. The balls are transported in a 70-meter long grate furnace, followed by a 40-meter long kiln furnace where the balls are dried, the iron in them oxidized and the balls sintered to the desired hardness in up to 1250 degrees Celsius. The final process step is slow and careful cooling in a rotating cooler with a diameter of 28 meters. This is the world’s largest sinter machine to date of the type grate-kiln-cooler. Production in the processing and pelletizing plant is controlled and monitored by operators in a common control room. The automation system is ABB’s System 800xA, including the operator environment. But LKAB wasn’t satisfied with just a functional control system; there is a more exceptional element here in a room next to the control room – a simulator for the control system.

In 2008, LKAB commissioned a new processing and pelletizing plant in Kiruna, KA3/KK4, increasing its yearly overall production from 24 to 28 million tons of iron ore pellets. It is an enormous facility with the capacity to produce five million tons of pellets each year.

“Ball-shaped pellets are used in our customers’ blast furnaces and direct-reduction furnaces, and there are considerable quality requirements on the size of the balls, their roundness and quality,” says Mats Renfors, automation engineer at LKAB Kiruna. In the new plant, the iron ore is ground down to powder, cleaned of phosphorus in a flotation process, supplemented with a binding agent, drained and rolled into balls. The balls are transported in a 70-meter long grate furnace, followed by a 40-meter long kiln furnace where the balls are dried, the iron in them oxidized and the balls sintered to the desired hardness in up to 1250 degrees Celsius. The final process step is slow and careful cooling in a rotating cooler with a diameter of 28 meters. This is the world’s largest sinter machine to date of the type grate-kiln-cooler. Production in the processing and pelletizing plant is controlled and monitored by operators in a common control room. The automation system is ABB’s System 800xA, including the operator environment. But LKAB wasn’t satisfied with just a functional control system; there is a more exceptional element here in a room next to the control room – a simulator for the control system.

At a leading edge with control system simulator

Simulators have traditionally been used for example by aviation, oil, gas and nuclear power industries, but when it comes to the mineral sector, LKAB is at the leading edge with its new simulator.

“We were early to realize the advantages of simulation as a part of our work with improving processes,” says Mats Renfors. “At the beginning of the 2000s, we had for one thing problems with dosage of binding agent in another pelletizing plant, and a consultant helped us with a number of simulations of both dosage and the process. Based on the simulation results, we made changes to the mechanics and the control systems, and obtained good solutions.”

Not long after, LKAB began the construction of the new processing and pelletizing plant KA3/KK4. The plant was formally opened with a grand ceremony in July 2008, and production started with the ABB 800xA control system. A few months later, the new simulator was in place, ready for a number of different tasks.

“We were early to realize the advantages of simulation as a part of our work with improving processes,” says Mats Renfors. “At the beginning of the 2000s, we had for one thing problems with dosage of binding agent in another pelletizing plant, and a consultant helped us with a number of simulations of both dosage and the process. Based on the simulation results, we made changes to the mechanics and the control systems, and obtained good solutions.”

Not long after, LKAB began the construction of the new processing and pelletizing plant KA3/KK4. The plant was formally opened with a grand ceremony in July 2008, and production started with the ABB 800xA control system. A few months later, the new simulator was in place, ready for a number of different tasks.